- support@4e-tec.com

- +86-17826001788

The Variable Frequency Hood System developed by 4e technology is widely used in commercial kitchens in various scenarios. It includes EW series – sprinkler self-cleaning range hood, EC series – ceiling range hood, EN series – grease filter hood, EB series – flame-retardant water-washed hood,hood monitoring components and fan control system to achieve on-demand ventilation and reduce energy consumption.

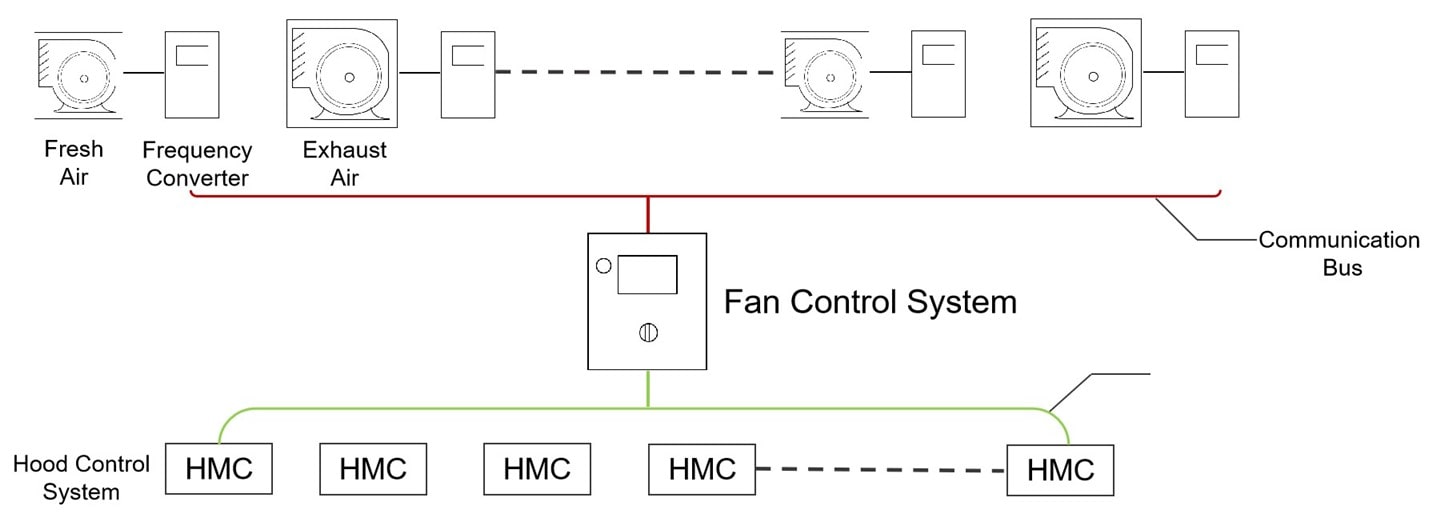

Variable Air Volume Control Principle: Hood Monitoring Components (HMC) on each section of the hood send the ventilation volume of that section through the communication bus to the Fan Control System (FCS). Based on the ventilation volume data provided by each section’s hood, the FCS controls the frequency converter to adjust the fan speed, achieving the purpose of regulating the air volume.

Infrared images show that within one minute of activating the stove, the temperature inside the hood spikes by 10 degrees Celsius. This temperature difference enables precise determination of the stove’s operational status. When the stove is on, the Hood Monitoring Components (HMC) open the exhaust valves and signal the Fan Control System (FCS) to increase exhaust and make-up air. When the stove is off, the HMC closes the valves and directs the FCS to reduce airflow.

Conclusion: According to calculations, reducing the fan operating frequency by 30% can decrease electricity consumption by over 65%, saving 192,000 Yuan (US$ 26,880) in electricity costs annually and reducing CO2 emissions by 28.5 tons.